Компания ООО "МАГНИТ плюс" () - российский разработчик, производитель и поставщик оборудования и инструмента для обработки металла с 1998 года.. Основная наша продукция - оборудование на основе постоянных магнитов. Производство: мы обладатели патентов на магнитные приспособления, в том числе, на магнитные грузозахваты с отключаемым магнитным полем. Все магнитные устройства и системы мы производим на собственных производственных мощностях в Санкт-Петербурге. Научная работа - разработка вспомогательного оборудования для сварочных работ: устройств для размагничивания,оборудования для снятия внутренних напряжений в металлоконструкциях без применения термообработки, устранение эффекта «магнитного дутья» при сварочных работах. Инновационные решения для промышленных производств на основе постоянных магнитов наши специалисты создают в тесном сотрудничестве с практиками, технологами предприятий. Мы открыты для сотрудничества и предлагаем наши опыт и знания для совместного поиска решений насущных проблем машиностроителей. Инженеры компании разрабатывают оборудование по индивидуальным заказам: магнитные сепараторы, магнитные решетки (железоотделители), магнитные распушители (разделители листового металла), магнитные траверсы, магнитный крепеж различного назначения. ООО «МАГНИТ плюс» является официальным дилером немецкого производителя профессионального инструмента и оборудования FEIN. Продукцию FEIN отличает высокая надежность, производительность и универсальность. Приглашаем технологов, механиков, сварщиков в демонстрационный зал в офисе компании. Мы готовы продемонстрировать все возможности предлагаемого оборудования. Здесь же проходит обучение персонала компаний-заказчиков после приобретения оборудования. Обучение и консультационная поддержка специалистов, работающих с нашим оборудованием - бесплатно на протяжении всего срока эксплуатации. Доставку осуществляем во все регионы России. Наиболее востребованная продукция МАГНИТ плюс: Магнитные захваты для подъема и перемещения стальных и чугунных грузов двух категорий на ферритовых магнитах, которые могут использоваться для работы с тонким листовым металлом, и на редкоземельных магнитах для других видов грузов. Магнитные плиты и призмы - станочные приспособления для шлифовальных и других металлообрабатывающих станков. Держатели магнитные и угольники магнитные для надежной фиксации деталей металлических конструкций в процессе сборочно-монтажных работ в нужном положении. Магнитная оснастка для закрепления контрольно-измерительных приборов: магнитные основания, штативы, стойки, держатели. Магнитные контакты обратного сварочного провода - удобная замена струбцин или клещевого зажима. Магнит компенсационный для устранения эффекта "магнитного дутья" при сварке. Устройства для размагничивание: настольные, ручные, мобильные.. Магнитная оснастка для крепления опалубки при производстве конструкций ЖБИ. Магнитный крепеж опалубки. Электрический кромкорез (снятие фаски) для обработки кромок труб, металлических листов и заготовок перед сваркой и покраской. Оборудование для упрочнения металлов: Технологический комплекс «Шмель» для упрочняющей обработки сварных соединений металлоконструкций методом ударного деформирования на ультразвуковой частоте( ультразвуковая обработка ). Технологический комплекс «ВТУ» для снижения остаточных сварочных напряжений, стабилизация геометрических размеров сварных и литых конструкций методом низкочастотной виброобработки сварных соединении. Станки на магнитном основании для корончатого сверления по металлу . Ленточные шлифовальные станки по металлу GRIT by FEIN. Профессиональный электроинструмент FEIN. Оборудование для монтажа труб ROTHENBERGER.

Make a safe deal with this supplier.

Apply

ООО "МАГНИТ плюс"

Санкт-Петербург, Russia

USD

342.56/pcs

Magnetic grippers are cheaper than Chinese ones! In stock! Delivery!

ООО "МАГНИТ плюс"

Санкт-Петербург, Russia

USD

8221.45/pcs

Laser interferometer for determining the magnitude, sign and direction of the main axes of stress. To register the measurement of residual stresses by recording the fields of small displacements in the studied area. The method is based on the elastic load arising in the local area of the investigated product by drilling through a hole through a small diameter and depth. The accuracy of determining the strain by this method reaches ± 130 nm; these are strains caused by low residual stresses. The laser interferometry method allows you to obtain accurate data on the magnitude, sign and direction of the main stress axes in 10 ... 15 min (in contrast to the trepanation method, where the period is calculated in weeks). The interferometer consists of: • An aluminum plate 10 mm thick, on which all optical elements are installed; • The bases with three support; • The mechanism of rotation of the optical axis; • A semiconductor laser emitting light in the green part of the spectrum; • A device that creates a divergent light flux; • Dividing mirror; • Digital video cameras with a lens; • Band-pass filter; • External protective casing; • Three permanent magnets on flexible bases. The interferometer must be rigidly attached to the test surface. Therefore, its supports have sharp carbide endings, which ensure penetration into the investigated surface. The introduction of the supports into the surface occurs, first of all, due to the attractive force of permanent magnets, as well as due to the mass of the device. All optical elements - laser, video camera with lens, dividing mirror, etc. are located in one optical plane, on the plate, which can be fixed at an angle of 90 or 45 degrees to the plane of the investigated surface. The semiconductor laser of the interferometer can be equipped with a separate power supply unit from the 220V network or a set of 5V batteries. The digital camcorder is equipped with a cable with a USB connector for connecting to a computer.

ООО "МАГНИТ плюс"

Санкт-Петербург, Russia

USD

22837.37/pcs

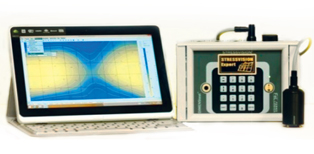

For measuring, indicating and visualizing mechanical (technological, residual), stresses in the base metal, welding seams and the heat-affected zone with the provision of information on the existence of conditions for the development of fractures in the studied area of the control object. For measuring, indicating and visualizing mechanical (technological, residual) stresses in the base metal, welds and the heat-affected zone with the provision of information on the presence of conditions for the development of fractures in the studied zone. • Layer-by-layer visualization of the stress state of the surface layers of the base metal. • Identification of dangerous and incipient defects that create a concentration of mechanical stresses. • Determining the conditions for the development of damage in the study area. The operator moves the sensor of the device step by step over the surface of the product area, the result is recorded electronically. After computer processing, cartograms of the distribution of mechanical stresses, stress concentration zones, etc. are built and displayed on the display. The degree of danger and the presence of conditions for the destruction of the section of the test product with the identified sections of KMN (concentration of mechanical stresses), KNN and gradients RGMN (the difference of the main mechanical stresses) is estimated by the common methodology (SP, RD, etc.). • Information is extracted in layers below the level of hardening from depths of 1-20 mm; • It is not necessary to clean the surface of the test object, as when working with acoustic voltage meters; • The control area is from 30x30 mm when measuring mechanical stresses and 80x80mm when building cartograms of the Russian State Standard of Materials; • Readiness for work no more than 0.5 min .; • Measurement time at one point, on average, 1 sec. STRESSVISION Expert v. 2.013 Minimum scanning area, mm 90 x 90 The number of scan nodes, min-max, pcs 25 - 93378 The maximum number of scanning zones, pcs 3700 Consumed current, A 0.25 Operating temperature range, ° C from - 10 to +55 Dimensions of the measuring unit, mm 87 x 227 x 167 Weight 1.8 kg The device is delivered in a shock-resistant case on wheels and with a retractable handle for convenient transportation. Six locks, a valve for balancing pressure during air travel. Inside: damping material with compartments for all components of the device.

ООО "МАГНИТ плюс"

Санкт-Петербург, Russia

USD

0.01/pcs

To measure and reduce residual mechanical stresses in metal structures after welding. TECHNOLOGICAL COMPLEX "ANTISTRESS 1" The complex includes: Technological complex “VTU-02MP” Mechanical stress scanner "STRESSVISION ANTISTRESS" TECHNOLOGICAL COMPLEX "ANTISTRESS 2" The complex includes: Technological complex "Bumblebee-1" Mechanical stress scanner "STRESSVISION ANTISTRESS" TECHNOLOGICAL COMPLEX "ANTISTRESS 3" The complex includes: Technological complex "Bumblebee-1" Technological complex “VTU-02MP” Mechanical stress scanner "STRESSVISION ANTISTRESS"

ООО "МАГНИТ плюс"

Санкт-Петербург, Russia

USD

8564.01/pcs

To reduce residual mechanical stresses by the method of low-frequency vibration processing (HBO) at resonant frequencies. The complex allows vibration processing of large parts at a resonant frequency. As a result, redistribution of internal stresses occurs, the product geometry is leveled, stress concentrators, as sources of future destruction of the metal, go away. Vibration processing makes it possible to avoid costly heat treatment with similar results. The workpiece or metal structure is placed on the vibration damper. A vibration exciter with adjustable imbalance is installed on the part, which allows you to determine the necessary processing parameters. Vibration processing lasts 15 to 30 minutes. Control measurements with the Stressvision Expert V.2.013 device demonstrate that mechanical stresses are removed and the metal is evenly stabilized. The device operates in three modes: manual, automatic run and automatic. During an automatic run, the operator determines the ranges of resonant frequencies. By selecting and setting the resonant frequency, the operator starts the automatic mode, during which the device supports operation at the set frequency. The processing time at a resonance of 15-20 minutes. Comparison of the most common methods for eliminating residual welding stresses

ООО "МАГНИТ плюс"

Санкт-Петербург, Russia

USD

7993.08/pcs

For hardening of welded joints by impact deformation at ultrasonic frequency. Installation Bumblebee allows you to directly process the weld zone by impact deformation at the ultrasonic frequency. This method can significantly reduce the level of residual technological stresses, and in some cases allows you to abandon post-weld heat treatment. Complex features • Reduction of residual welding stresses due to the formation of compressive surface stresses • Reducing the likelihood of defects • Formation of a surface hardening layer with resistance to cracking. Features and Benefits • Compactness and mobility • Versatility Can be used for structures of various composition and metal structure • Profitability Significant reduction in energy, time and labor costs compared to other methods of reducing mechanical stress • There is no effect on the chemical composition and structure of the metal • Environmental Safety.

ООО "МАГНИТ плюс"

Санкт-Петербург, Russia

USD

228.37/pcs

Lifting magnets or load grips are designed to hold loads and workpieces from ferromagnetic materials. Retention is due to a constant magnetic field, the source of which is a permanent magnet. Cargo captures are used for transportation in the conditions of procurement, mechanical repair and metalworking shops, steel rental warehouses, during installation and other types of work. We produce a wide range of models, satisfy any needs of enterprises and select a gripper with characteristics for specific goals and objectives of the production process: from moving small parts and piece blanks to large-sized products and metal structures. For lifting and transporting heavy or long loads (rails, beams, sheets, and another profile), we recommend using a combination of several magnetic grips of the same type suspended on a beam. The advantage of magnetic grippers is that they do not require a power source, are reliable and safe, retain properties during long-term operation, are compact and light in weight. All captures have their own mechanism of separation of the magnet from the surface. The cam mechanism creates an air gap and the grip is easily removed. The rotary on / off mechanism is an integrated mechanism that, when the handle is rotated, combines the poles of the magnets, which excites the magnetic field. This mechanism provides insurance against accidental disconnection of the magnetic field. We produce magnetic captures on rare earth magnets and on ferrite magnets. The advantage of captures on rare-earth magnets: high power (pulling force), small size and weight, but they do not work with thin metal. Captures on ferrite magnets with the same load capacity are more heavy and larger in size, but a short-circuited magnetic field captures one sheet from a pack of metal without magnetizing the next. The smallest manual grab in the line with its own weight less than one and a half kilograms, is able to hold the load up to 40 kilograms, while the pull-out force is three times higher than the rated load capacity. This means that under ideal conditions: the condition and shape of the working surfaces, the chemical composition and structure of the cargo material, this magnet can hold up to 120 kg.

ООО "МАГНИТ плюс"

Санкт-Петербург, Russia

USD

887.94/pcs

About company

| Categories: | Address: |

|---|---|

| Safety & ecology, Food & agro machinery, equipment, Industrial Equipments and Machines, Other equipments and machines, Electrical equipment, Welding Equipment and Machines, Agriculture Machinery & Equipment, Construction Machinery & Equipment, Equipment for Production of Construction Machines, Machinery & equipment, Metal Processing Machinery, Electrical equipment and parts | Russia, Санкт-Петербург, 190020 Россия, Санкт-Петербург, наб. Обводного канала, д. 223-225, лит. "С" |

Contact supplier

Supplier:

"Узлегпром"

Product:

Supplier:

Min. order:

Directory

Marketing department:

Marketing department:

Marketing department:

Information

Inform manager that you found the product on Qoovee

The contact details of the supplier is not available!

Send message