Product description

Disinfection Door Application Features:

1.Face recognition system.

The system can record 20,000 face cases, which can effectively check the identity of people in and out of fixed and dense places such as office buildings, schools, communities, factories, etc., automatically intercept outsiders, and realize rapid control of personnel during the outbreak.

2. Automatic induction spray function.

The equipment is equipped with a microwave moving object sensor. After detecting the entry of someone, it starts the fog machine and sprays disinfectant into the disinfection channel.

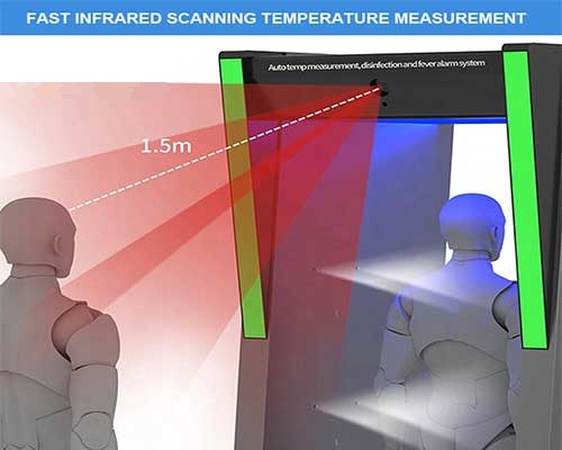

3. Infrared human body temperature measurement, sound and light alarm.

Using high-precision industrial infrared spectroscopy sensor, factory calibration by black body radiation source, can achieve non-contact measurement of body temperature, fast and reliable, can effectively avoid cross-infection, and collect body temperature in real-time.

4. Food-grade disinfection products.

The equipment adopts a food-grade disinfectant, which is widely used in the disinfection of food, tap water, vegetables, and fruits.

5. Contact alcohol disinfector for hand.

The temperature measurement area of the equipment is specially equipped with hand sterilizers, non-contact induction spraying, safe and hygienic, and can carry out effective sterilization.

6. Non-angle-of-attack spray does not stimulate human facial organs.

The mist outlet of the disinfection channel is designed with a low angle of attack to avoid discomfort caused by the direct spray of mist on the human face.

7. Disinfection function of soles and wheels.

There is a carpet containing disinfectant in the middle of the disinfection channel, which can disinfect the soles of passing people, wheels of wheelchairs, toy cars, and so on.

8. Device status reminder function.

The equipment has the status display of work, lack of liquid, light, etc. so that the equipment management personnel can accurately grasp the operation status of the equipment in real-time. The fog-making equipment has an anti-dry burning function, which can effectively prevent damage to the equipment caused by improper operation.

9.Automatic fluid replacement function.

The equipment is equipped with a 20L large-capacity liquid storage tank, which can automatically refill the atomization tank, reduce the workload of the operator, and can be used for more than one day without the need to add disinfectant.

10.Waste liquid collection function.

The bottom of the equipment is designed with a waste liquid collection tank and an active waste liquid collection tank, which can completely collect the waste liquid remaining after the equipment is sterilized and concentrate on hazardous waste treatment to prevent environmental pollution.

11. Channel lighting function.

The equipment has fully considered the use scene, and the channel is equipped with an LED lighting function, which is convenient for use at night or in a dark light environment.

12. Removable function.

The disinfection tunnel equipment has two sets of universal casters with brakes and two sets of directional casters with brakes. The auxiliary slopes on both sides are foldable, which is convenient for moving positions, quick layout, reducing storage space occupation, using nylon thread, adapting to various road conditions.

Operating Principle:

Using triple disinfection of ultraviolet, plasma, and light-spray atomization, matrix-type dead-end whole-body disinfection, non-contact disinfection, more thorough disinfection.

The control disinfection cabinet has three buttons and starts in turn.

Ultrasonic spray disinfection.

Ultraviolet disinfection.

Blue light start button, the device can operate normally.

After the disinfection lamp button is turned on, the ultraviolet disinfection on both sides and the plasma disinfection on the top are turned on.

After the disinfection button is turned on, the light wave atomization is turned on, which is divided into low gear and high gear.

Intelligent Atomization Disinfection Door Operation Instructions:

1. Open the disinfectant storage cabinet, put the disinfectant in the storage cabinet, and connect the pipe diameter.

2. Turn on the power.

3. Start in turn:

a. Ultrasonic spray disinfection

b. Ozone disinfection

c. The button and device to start blue light can work normally.

4. Close: close in turn

a. Ultrasonic spray disinfection

b. Ozone disinfection

c. The start button of the blue light, the device can be turned off, the temperature measurement system can be started automatically

5. Water replenishment: add disinfectant according to the dosage to ensure a certain level of atomized water.

Learn more