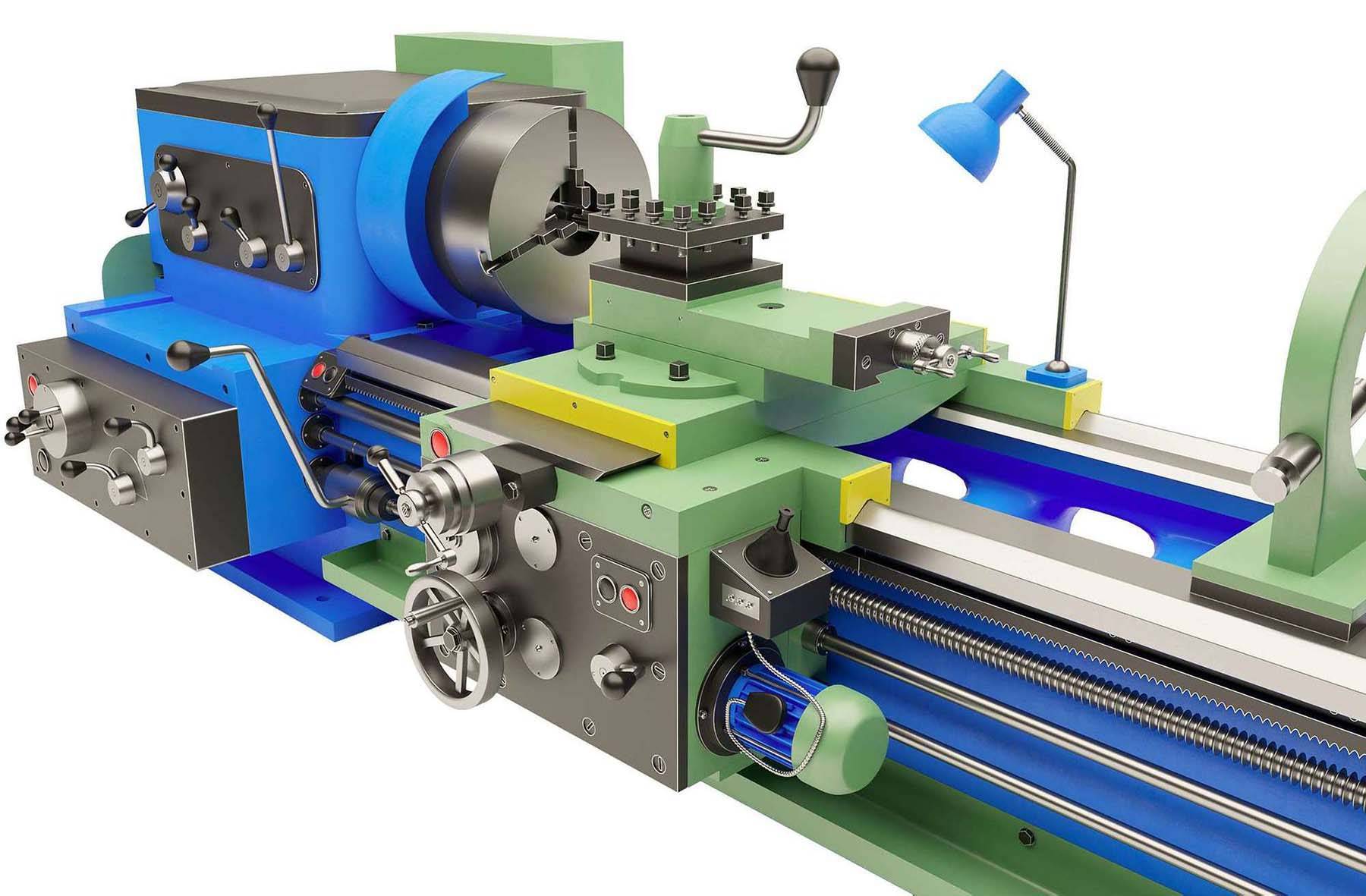

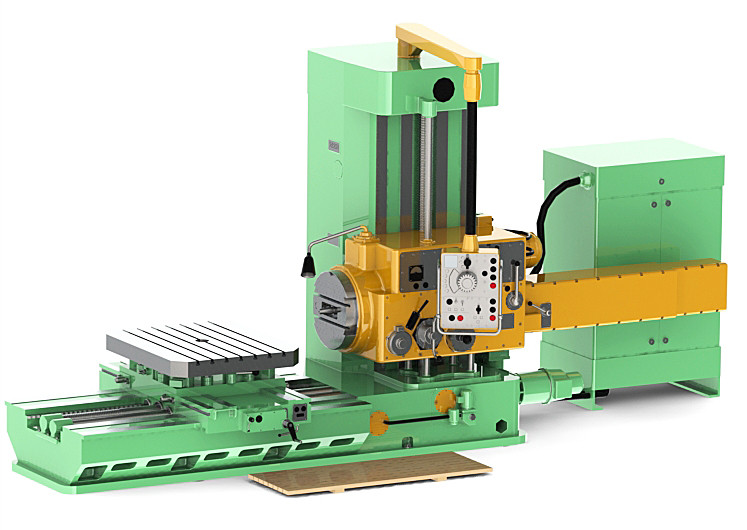

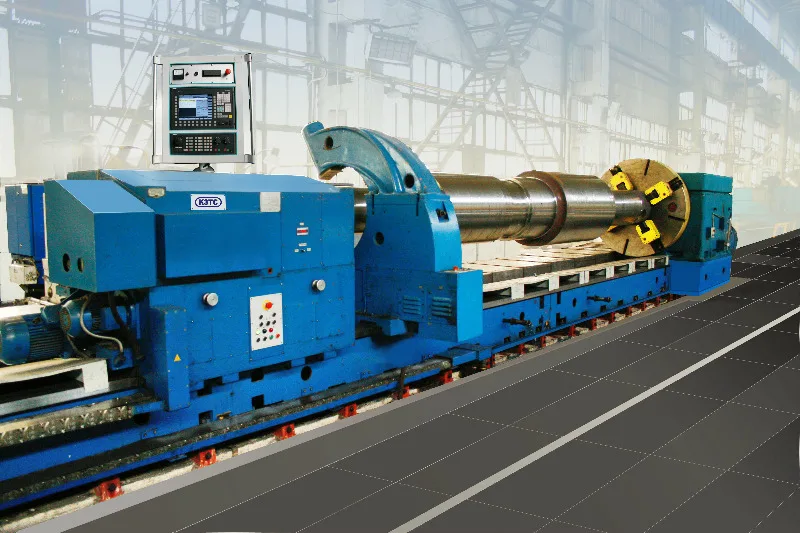

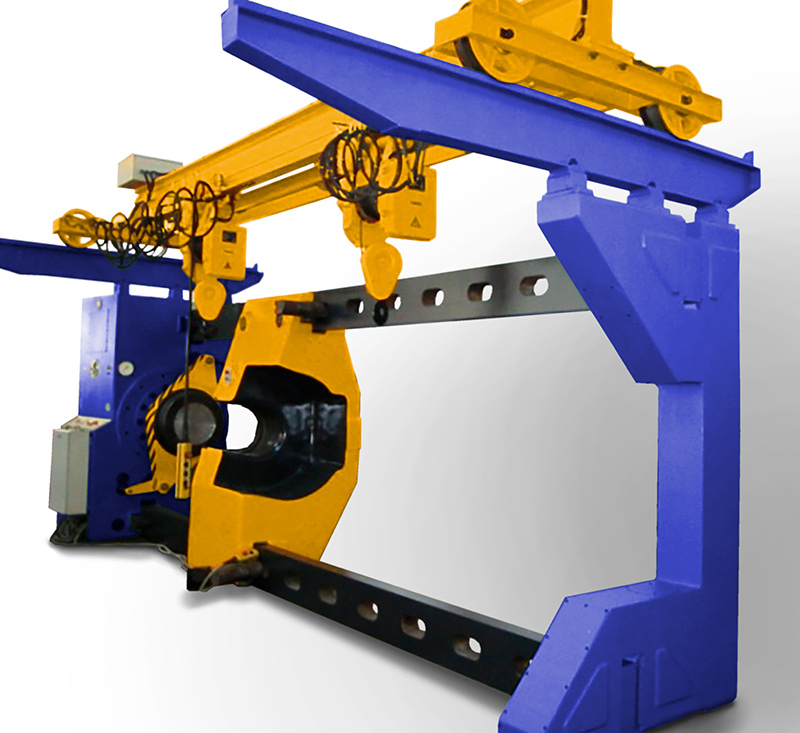

- We carry out high-quality overhaul of metal-cutting and metal-working equipment, and, if necessary, modernization. We offer a full range of machine repair services. In the process of repairing machines, technical specifications, accuracy parameters, as well as the appearance of machines that have served for many years, are fully restored, and obsolete electrical equipment, elements of hydraulic, pneumatic systems, measuring devices and CNCs are replaced with modern ones. When designing a machine overhaul, it is planned not only to replace worn and defective parts with new ones, but also to use new technologies in the manufacture of one or another assembly, which allows to achieve excellent accuracy indicators of the machine, increase its productivity and reduce energy supply. We make maintenance. We give preference to heavy machines. The main activity is the overhaul of machine tools. We do not just provide high-quality repair of metal-cutting and metal-working equipment, we help to find the best options in each case.

The scope of activity includes:

- supply of machine tools and special equipment, spare parts and components for machine-building, metallurgy, energy industry and railway transport;

- project development and equipment supply, preparation of technical documentation, turnkey installation and commissioning;

- there is experience in carrying out various types of repair of metalworking machines, as well as commissioning;

- medium and major repairs, restoration of technical characteristics, modernization and automation of equipment;

- We have extensive experience in the design and supply of equipment in the markets of Ukraine, Russia, CIS countries;

- the accumulated wide experience in the selection and commissioning of high-precision equipment, in its modernization and equipping with various auxiliary devices, as well as various electronic devices and CNC systems of the most famous foreign companies, allows us to offer the customer modern high-quality products that can fulfill all the tasks;

- the company's products cover the main groups of heterogeneous metal-cutting and other technological equipment having complex kinematics, complex electrical, hydraulic devices, as well as numerical control systems that make it possible to work on a program in automatic mode, with processing accuracy in the first and second class;

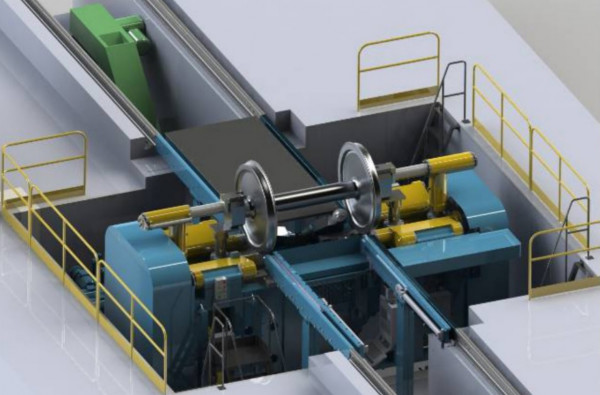

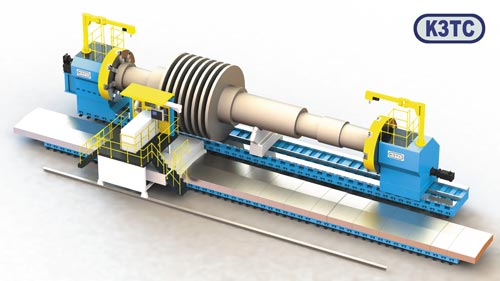

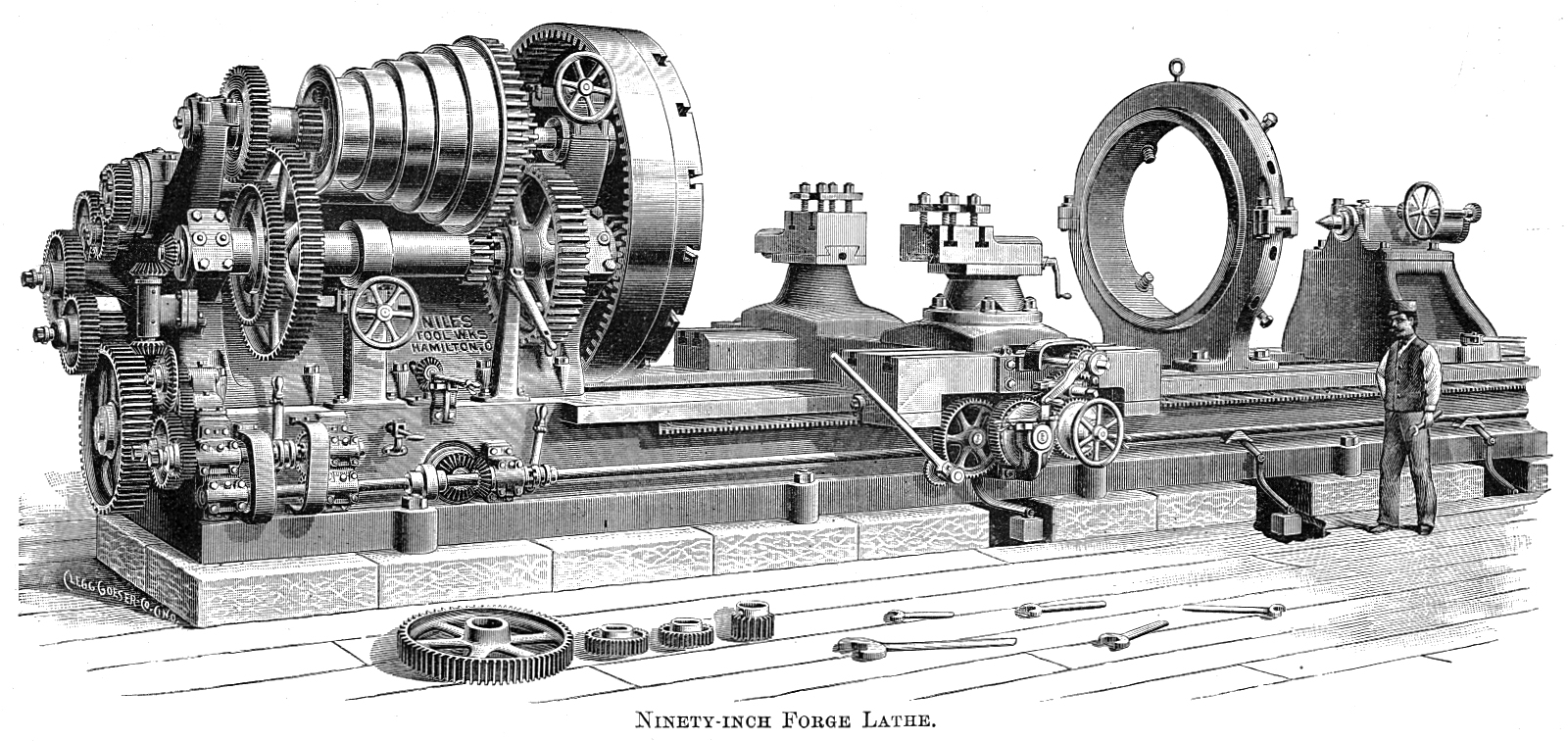

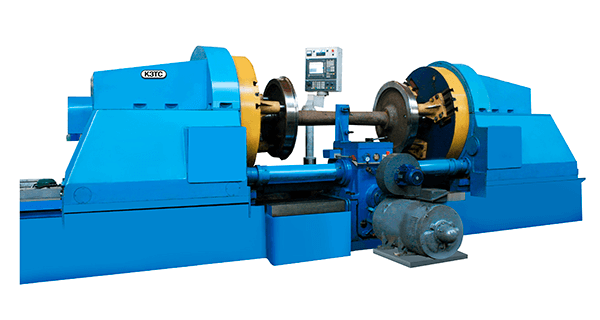

- the supplied machines are heavy and unique metalworking machines, both with manual control and equipped with positional and contour systems of numerical program control;

It is possible to supply other models of machines not specified in this proposal, according to your application.

Our company has experience in the supply, modernization and repair of machine tools from different manufacturers, in particular:

- supplies of components to engineering plants;

- spare parts, repair, modernization and maintenance of metal-cutting machines, including medium and heavy turning, boring, longitudinally milling, wheel-milling and wheel-turning, etc.

Services performed for metalworking machines:

- repair;

- modernization;

- service maintenance;

- restoration of machines;

- diagnostics of machines;

- metalworking on CNC machines;

- modernization of CNC machines;

- adjustment of machines;

- repair of metal cutting machines;

- Services for the repair and modernization of lathes;

- repair and maintenance services of equipment and machines with numerical control;

- modernization of machines

Development and design:

- according to the technical specifications of the customer, highly qualified specialists will carry out the development of the project for the manufacture and supply of equipment, carry out all the necessary calculations and prepare technical documentation.

Repair and modernization:

- having a good production base, we make small, medium and major repairs of machine tools and other equipment. We make restoration of technical characteristics, modernization and automation.

Overhaul includes the following work:

- repair, completion and manufacture of machine parts of the machine;

- manufacture and replacement of all worn parts and assemblies;

- replacement of rubber goods, bearings, etc .;

- repair, restoration and complete equipment of the electrical part of the machine;

- restoration of all technical and accuracy parameters of the machine.

- repair is carried out according to technical documentation and technological process.

- we guarantee the quality of work performed.

- Warranty period - 12 months.

Installation supervision and commissioning:

- Our experts will perform installation and commissioning, commissioning of equipment on a turn-key basis.

Machine tools: Drilling machines, Special machines. Lathes Milling machines, gear-milling and gear-processing. Grinding machines. Boring. Automatic machines, semi-automatic machines. Mortising, planing machines. Guillotine shears. Pipe benders, bending machines. Forging equipment. Presses and sheet bending machines, Crank and hydraulic presses. Pipe benders. Forging hammers.

Explosive machines, test presses PSU, PS, MS, PMM, UMM, MUP, HMS, GRM, RM