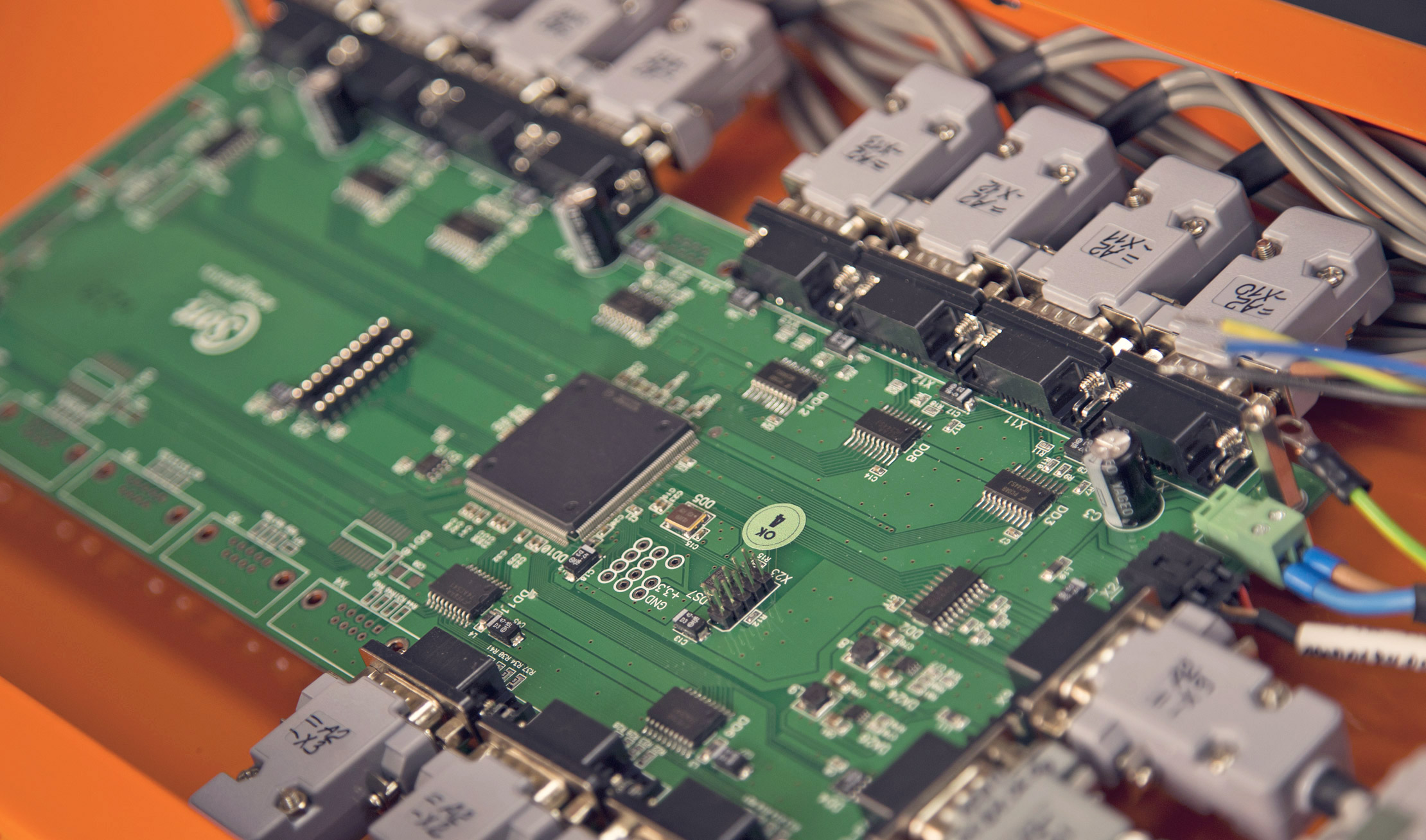

Since 2007, CSort has been developing and manufacturing high-tech equipment for sorting bulk products - color sorters. Today CSort is the Russian leader in terms of sales of its own color sorters; it is a member of the Rosspetsmash Association and the Altai cluster of agricultural engineering. CSort has representative offices in 9 countries of the world, equipment supplies go to 27 countries. In 2019, the company became a participant in the priority project of the Ministry of Economic Development of Russia "National Champions", and CSort was also recognized as the best exporter of Siberia in the nomination "Exporter of the Year in the Field of High Technologies" (competition of the Russian Export Center). CSort has representative offices in the following cities: Barnaul (head office); Voronezh; Krasnodar; Novosibirsk; Samara. The CSort plant is located in Russia. It includes a development center, a manufacturing facility, a quality assurance and control service, a sales office, and an international trade department.

Make a safe deal with this supplier.

Apply

LLC "CSort"

Russia

USD

193416.0 - 804260.0/pcs

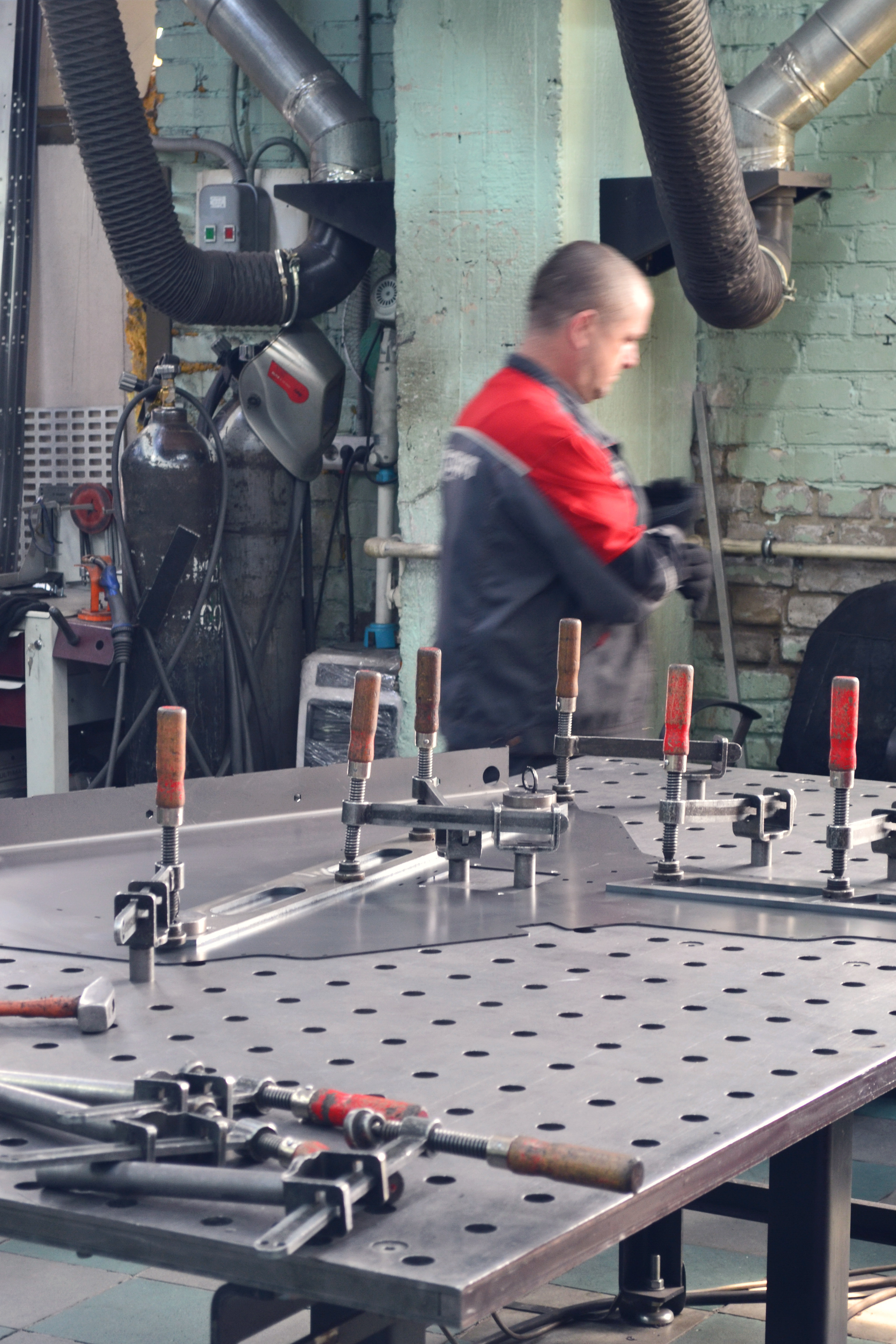

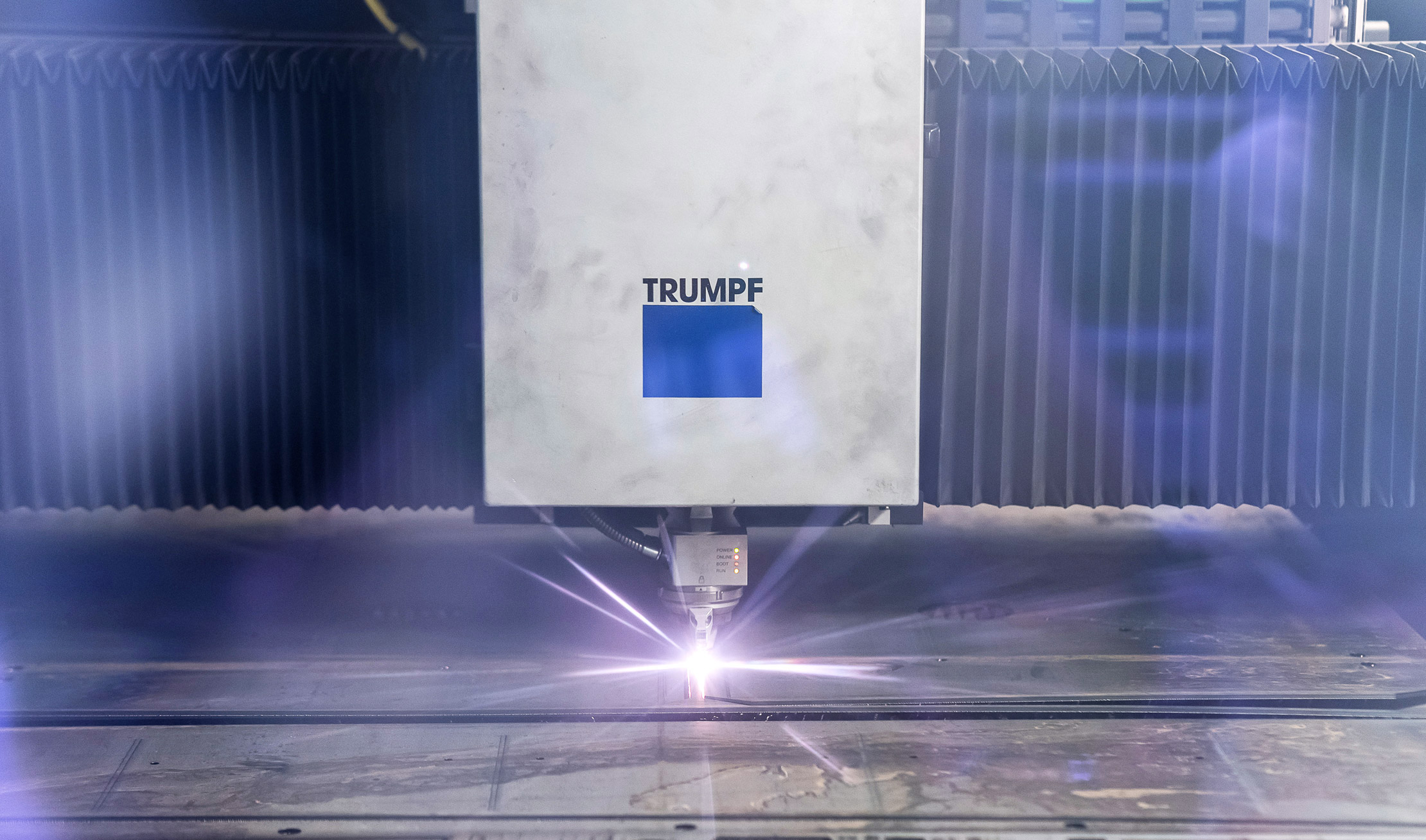

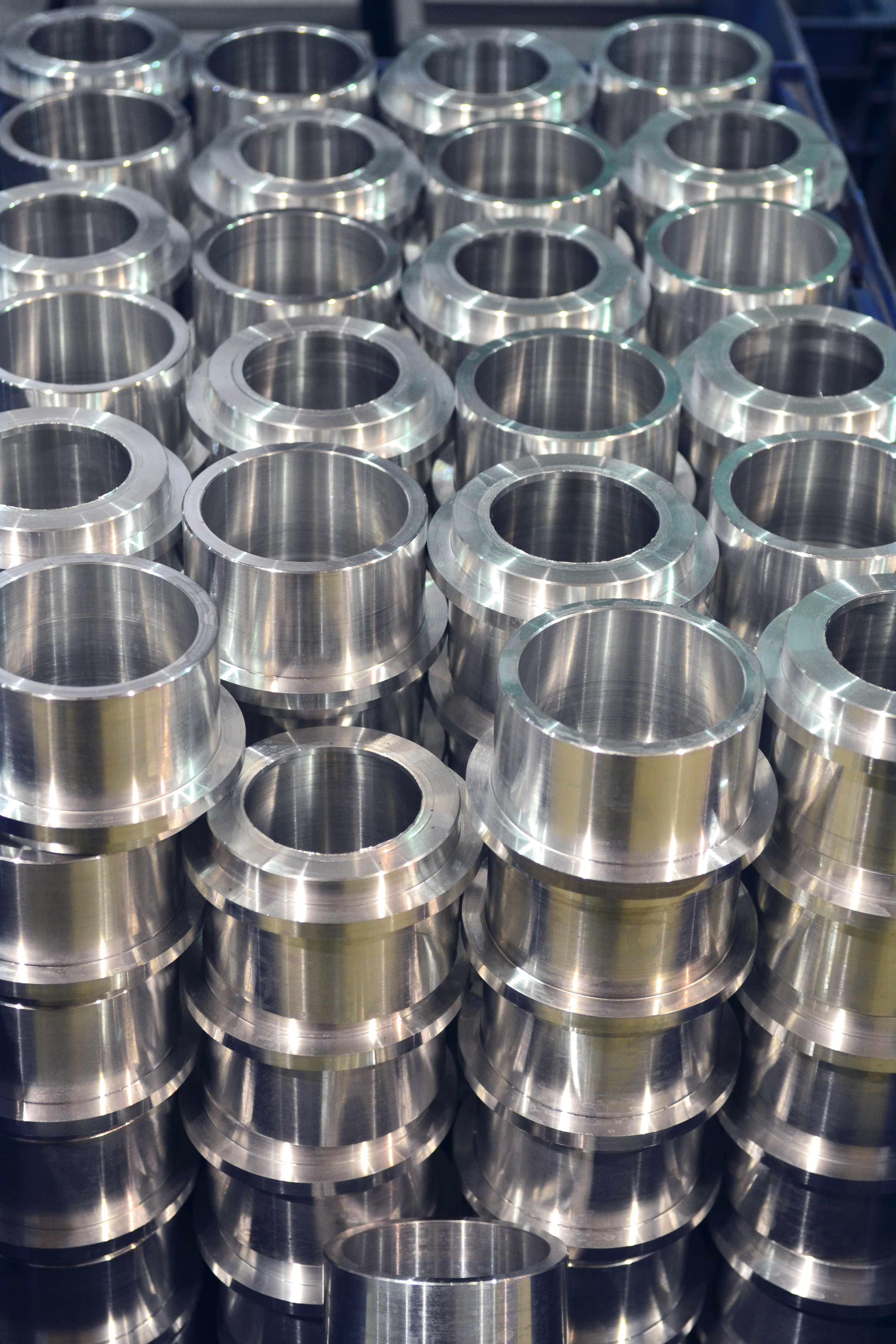

Quick and easy assembly Produced on Trumpf's precision laser bending machines, structural elements are assembled approximately 30-50% faster and less skilled personnel are required for assembly. Self-supporting construction The rigid self-supporting construction of the bucket elevator due to the large number of bends and the thickness of the used sheet metal of 1.5 and 3 mm allows installing bucket elevators up to 45 meters without intermediate supports. Durable construction lasts much longer. Gentle transport The working speed of our elevators is 1.5-2.5 m/s, while that of competitors is usually 2.8-3.4 m/s, with the same performance, due to this, the transported product is less injured. Galvanized version, stainless version Galvanized version provides the best corrosion protection at minimum cost. Stainless steel version available. Transportation of material over a wide range of speeds The specially designed shape of the elevator head provides effective product discharge at a belt speed of 1.5 to 2.5 m/s, which makes it possible not to injure the material during transportation. Automation and safety Elevators can be equipped with all sensors: belt drift sensors, pressure sensor both in the head and shoe of the elevator, belt speed control sensor, reverse device. All holes for these sensors are already laid and closed. Compactness Our elevators have smaller dimensions with the same performance. This is important when there is not enough space to install a noria. Certification The produced bucket elevators have certificates of conformity, a hygiene certificate, a permit from Rostekhnadzor, and CE certificates of the European Union.

LLC "CSort"

Russia

USD

2208.56/pcs

Modern bucket elevators CSE 15 by SiSort, with a capacity of up to 15 m³/h, provide economical, fast and safe transportation of bulk material, can be used in various industries. CSE 15 bucket elevators are equipped with plastic buckets, the belt speed range is from 1.1 to 2.5 m/s, they can be used for transporting animal feed, grain or seeds. The start of the electric motor is smooth, which eliminates the possibility of breaking the buckets and cutting the keys on the upper head of the bucket elevator, and allows the use of electric motors of lower power. Convenience in repair, inspection, maintenance is inherent in the design features. The quality of workmanship and thoughtfulness of the design of elevators. Fast installation. In our elevators, more buckets per 1 m of belt are installed, due to this, the wear of buckets is less by 20-40%. The exit in the head has a slope of 35 degrees. This saves installation height. In the basic configuration, all models of bucket elevators have a lining of the head. All elevators are equipped with two suction pipes in the base.

LLC "CSort"

Russia

USD

11076.12/pcs

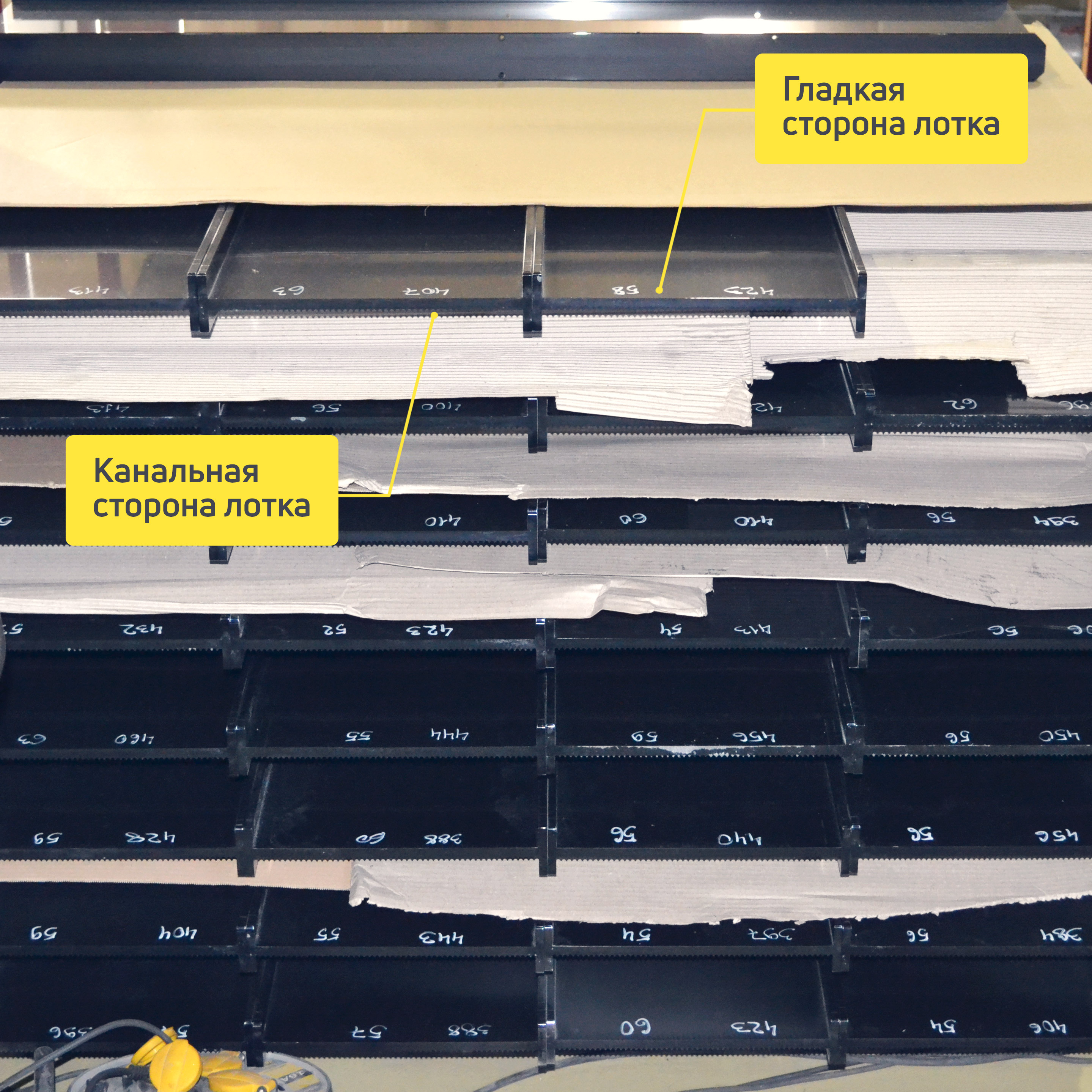

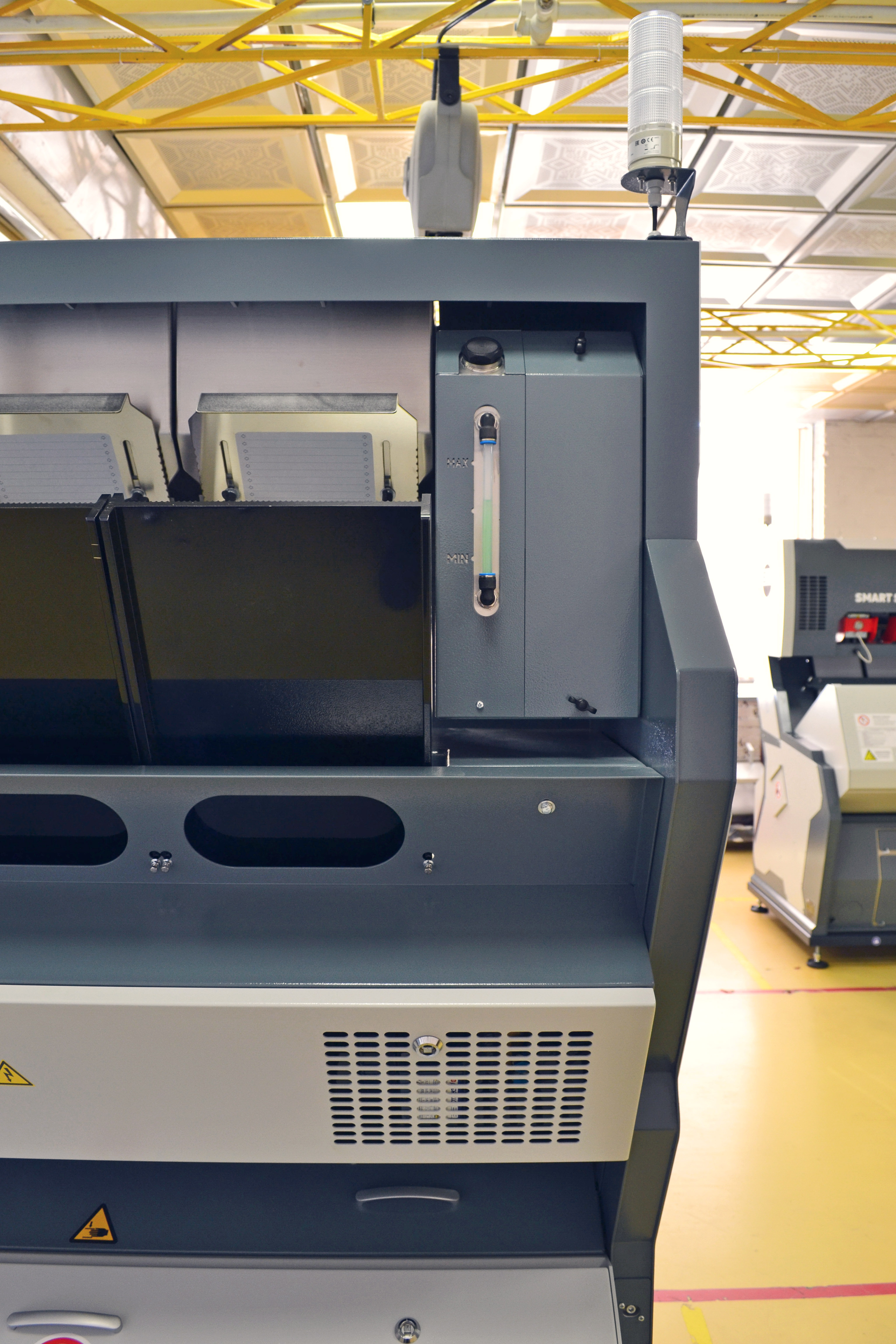

Mini-sorter MiniSort is a single-pan, compact sorter with high-resolution color cameras - 5400 pixels. Designed for sorting bulk materials with high accuracy, productivity and low cost. For companies with a small volume of raw materials, it shows a good return on investment. Application: Improving the quality of commercial grains Preparing seeds with low losses Sorting wild plants Removing intractable impurities Preparing raw materials in mini-mills Sorting coffee for roasters and coffee shop suppliers Sorting oilseeds Sorting minerals Sorting plastics by color (PET granules, flakes) Features Subtle color differences Two color cameras on a tray (5400 pixels) allow you to distinguish the smallest defects. Sorting by shape The software is able to analyze the shape parameters, which significantly expands the range of tasks to be solved. Automatic adjustment The MiniSort device implements automatic adjustment to the product - this is the convenience of work and high-quality results in a shorter time. Sorting visualization High-quality visualization allows you to control the sorting settings in real time. Heated trays Using the heated trays is ideal when sorting oilseeds. Portability The MiniSort is equipped with wheels and can be moved by one person. The dimensions of the device allow it to be transported in the trunk. High Profitability MiniSort delivers performance and quality results (per tray) that are comparable to larger machines, but at a significantly lower cost. Low solution cost and quick payback are the advantages of the MiniSort compact color sorter. Specifications 1 Number of channels, pcs. 32 2 Productivity (wheat), t / h, not less * 0.5 3 Cleaning factor,%, not less * 99 4 Resolution of the CCD matrix (per tray), pixel 5400 5 Nominal power consumption, kW 0.8 6 Pressure air, MPa 0.4 7 Air purity class according to GOST 17433, ISO 8573-1: for solid particles 1 for humidity 4 for oil content 1 8 Air consumption for the technological process (wheat), m³ / hour, no more * from 12 to 36 9 Product weight, kg, no more: 165 10 Class of protection against electric shock according to GOST IEC 61140-2012 I 11 Degree of protection of the shell according to GOST 14254 IP54 12 Ambient temperature, ° С from 5 to 40 13 Relative humidity at a temperature of 25 ° С,% from 20 to 80 14 Service life, years 10 * With an initial contamination of no more than 2%, the volumetric weight of the product is 0.750 t / m³.

About company

Contact supplier

Supplier:

"Узлегпром"

Product:

Supplier:

Min. order:

Directory

Marketing department:

Marketing department:

Marketing department:

Information

Inform manager that you found the product on Qoovee

The contact details of the supplier is not available!

Send message